To maintain OEKO-TEX® Standard 100 certification, every finished product must be linked to valid OEKO-TEX® certificates for its raw materials. With thousands of fabrics, elastics, and trims, this became a massive tracking challenge. Certificates were scattered across emails, spreadsheets, and file shares — making renewals, expirations, and audits time-consuming and stressful. I built an internal system to manage raw materials and their OEKO-TEX® certificates at scale, ensuring products could be certified quickly and reliably. The Challenge Scattered records: Certificates lived in multiple places with no single source of truth. Manual tracking: Expirations and renewals were tracked by hand, often missed until the last minute. Complex mapping: Finished products use multiple materials; linking each to valid certificates was error-prone. Audit pressure: Generating proof of compliance during audits was a scramble. The Solution I developed a centralized certification management system: A structured database of raw materials and their suppliers, each tied to OEKO-TEX® certificates and expiration dates. A linking engine that connects raw materials to finished products, ensuring certification traceability. Automated alerts for upcoming certificate expirations and renewals. Searchable reporting that produces auditor-ready documentation in minutes. Results & Business Impact Traceability: Every product can be verified against valid OEKO-TEX® certificates. Efficiency: Compliance management time reduced from days to hours. Audit readiness: Certificates and product mappings available at the click of a button. Reduced risk: Proactive alerts prevent expired certificates from slipping through. Features Delivered Centralized certificate repository. Expiration and renewal tracking with reminders. Many-to-many mapping between raw materials and finished products. Auditor-ready compliance reports. Role-based security and controlled data entry.

Project Overview

To maintain OEKO-TEX® Standard 100 certification, every finished product must be linked to valid OEKO-TEX® certificates for its raw materials. With thousands of fabrics, elastics, and trims, this became a massive tracking challenge. Certificates were scattered across emails, spreadsheets, and file shares — making renewals, expirations, and audits time-consuming and stressful.

I built an internal system to manage raw materials and their OEKO-TEX® certificates at scale, ensuring products could be certified quickly and reliably.

The Challenge

Scattered records: Certificates lived in multiple places with no single source of truth.

Manual tracking: Expirations and renewals were tracked by hand, often missed until the last minute.

Complex mapping: Finished products use multiple materials; linking each to valid certificates was error-prone.

Audit pressure: Generating proof of compliance during audits was a scramble.

The Solution

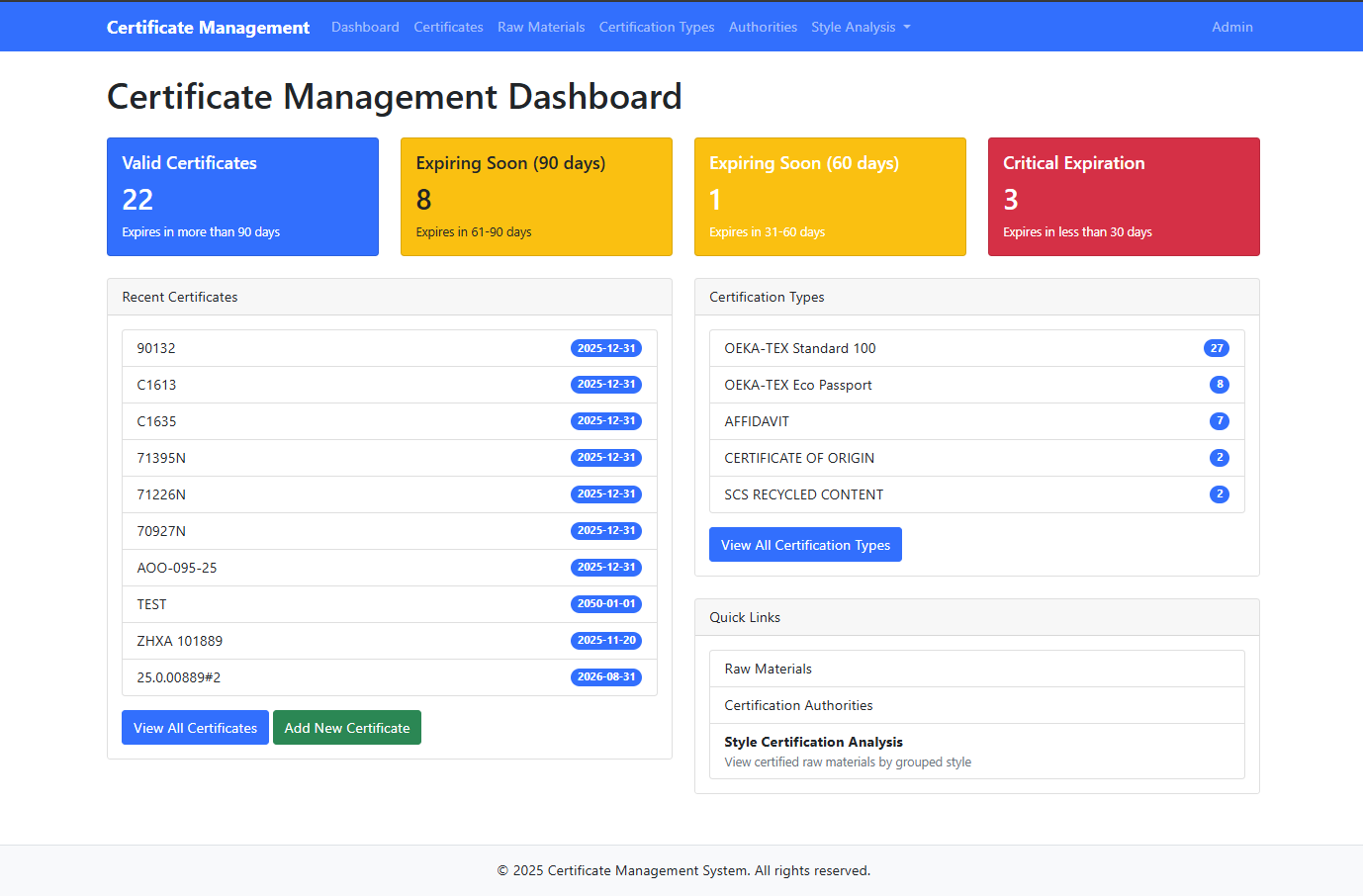

I developed a centralized certification management system:

A structured database of raw materials and their suppliers, each tied to OEKO-TEX® certificates and expiration dates.

A linking engine that connects raw materials to finished products, ensuring certification traceability.

Automated alerts for upcoming certificate expirations and renewals.

Searchable reporting that produces auditor-ready documentation in minutes.

Results & Business Impact

Traceability: Every product can be verified against valid OEKO-TEX® certificates.

Efficiency: Compliance management time reduced from days to hours.

Audit readiness: Certificates and product mappings available at the click of a button.

Reduced risk: Proactive alerts prevent expired certificates from slipping through.

Features Delivered

Centralized certificate repository.

Expiration and renewal tracking with reminders.

Many-to-many mapping between raw materials and finished products.

Auditor-ready compliance reports.

Role-based security and controlled data entry.

Project Details

Web Application

Completed

Related Projects

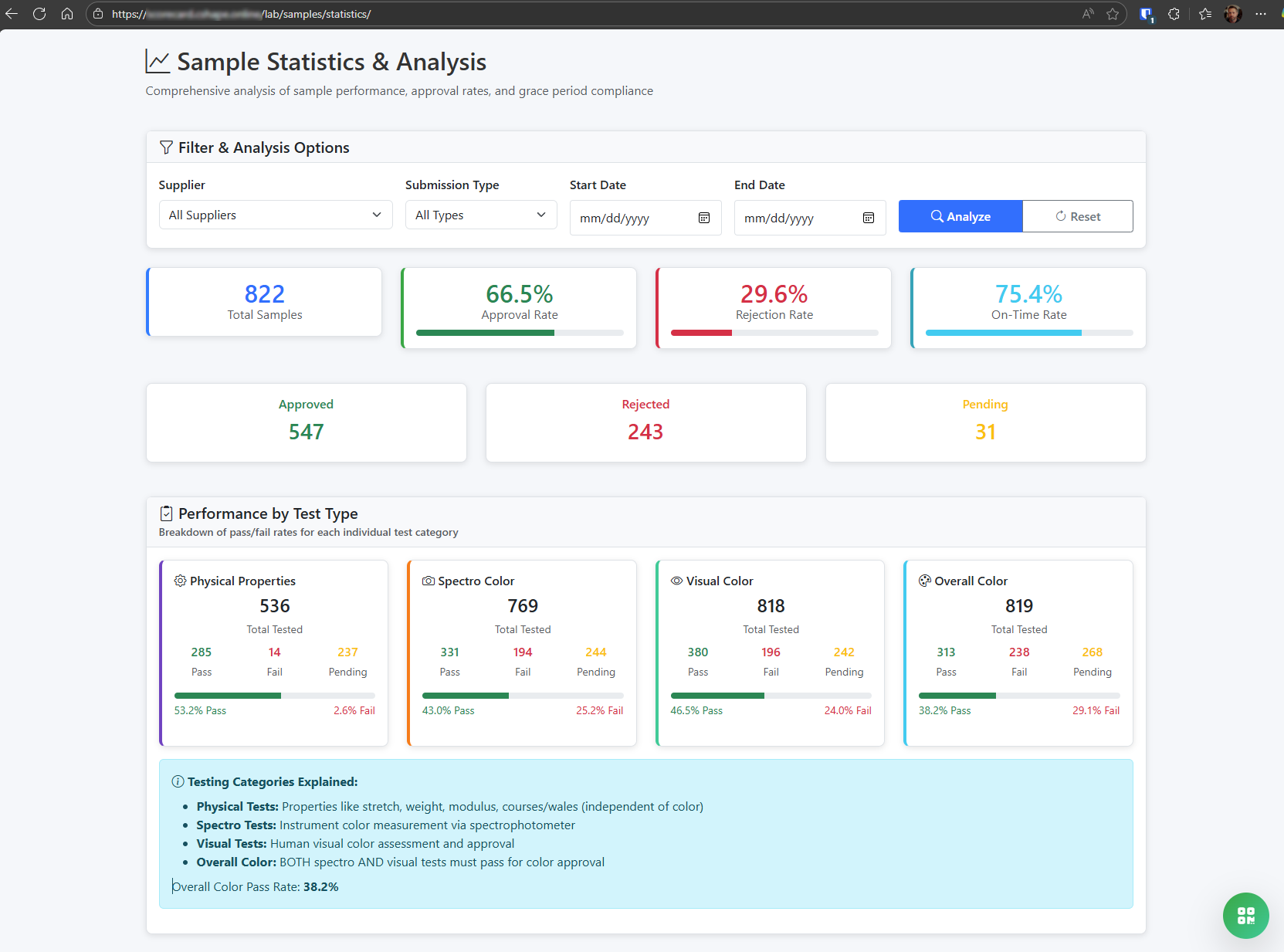

Track supplier raw material submittals across multiple submittal types. Lab dips, strike-offs, and bulk submittals …

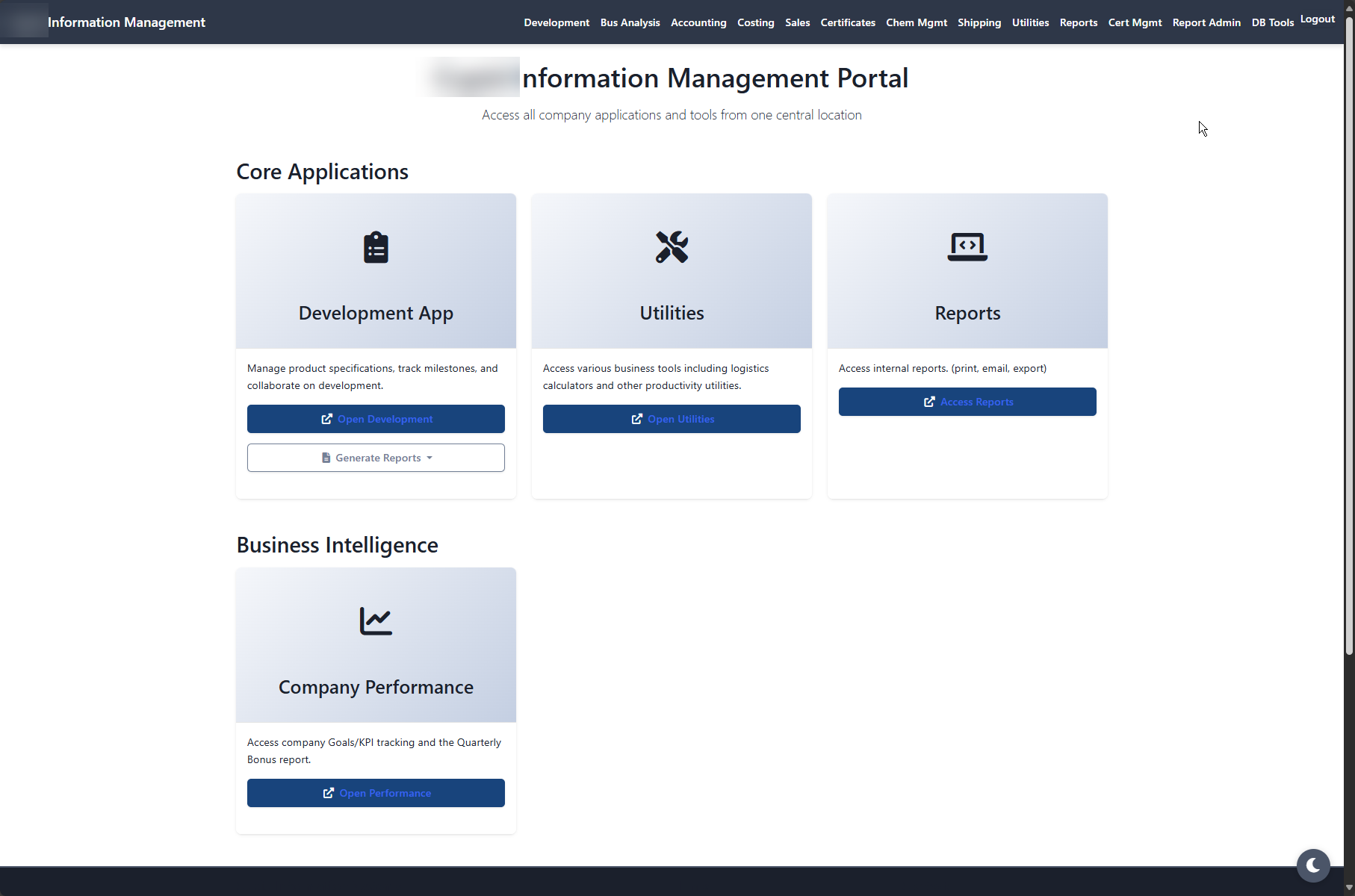

The Problem: Teams were stuck in 5250 emulators and rigid RPG reports. Simple tasks took …